-

1935

-

1938

Hochfeste Schrauben

Hochfeste Schrauben -

1941

Labor für Qualitätsprüfung

Labor für Qualitätsprüfung -

1945

Neubeginn

Neubeginn -

1954

Hydraulische Stahlschneidemaschine

Hydraulische Stahlschneidemaschine -

1955

2. Werk in Homberg (Ohm)

2. Werk in Homberg (Ohm) -

1956

Die "Kellermann-Klein" Formel

Die "Kellermann-Klein" Formel -

1959

Vollautomatische Herstellung

Vollautomatische Herstellung -

1970

3. Werk in Alsfeld

3. Werk in Alsfeld -

1973

Die nächste Generation

Die nächste Generation -

1974

Lieferung in die USA

Lieferung in die USA -

1980

Mit dem 4. Werk in Spanien beginnt die Expansion ins Ausland

Mit dem 4. Werk in Spanien beginnt die Expansion ins Ausland -

1986

Vollautomatisiertes Hochregallager

Vollautomatisiertes Hochregallager -

1992

5. Werk in Tschechien und neues Entwicklungszentrum

5. Werk in Tschechien und neues Entwicklungszentrum -

1995

Übernahme G.P. DUPONT in den USA (Werke 6,7 und 8)

Übernahme G.P. DUPONT in den USA (Werke 6,7 und 8) -

1999

Gründung von "FACIL"

Gründung von "FACIL" -

2002

Teile für 1 Million Fahrzeuge

Teile für 1 Million Fahrzeuge -

2004

Lieferung nach China

Lieferung nach China -

2006

FACIL mit 8 Standorten

FACIL mit 8 Standorten -

2007

Modernisierung und Erweiterung

Modernisierung und Erweiterung -

2007

Werkzeugbau in der Slowakei als 9. Produktionsstandort

Werkzeugbau in der Slowakei als 9. Produktionsstandort -

2009

Globale Kooperation mit der Aoyama Seisakusho-Gruppe in Japan

Globale Kooperation mit der Aoyama Seisakusho-Gruppe in Japan -

2010

Vertriebsgesellschaften in China und Japan

Vertriebsgesellschaften in China und Japan -

2013

Neues Logistikzentrum in Tschechien

Neues Logistikzentrum in Tschechien -

2013

Neuer Produktionsstandort in China

Neuer Produktionsstandort in China -

2017

KAMAX jetzt auch in Indien

KAMAX jetzt auch in Indien -

2017

Neuer Standort in Rochester Hills

Neuer Standort in Rochester Hills -

2018

Eröffnung des Aus- und Weiterbildungszentrums in Homberg

Eröffnung des Aus- und Weiterbildungszentrums in Homberg -

2019

Neuer Standort in León (Mexiko)

Neuer Standort in León (Mexiko) -

2020

Gründung der nexineer digital GmbH

Gründung der nexineer digital GmbH -

2021

Mehrheitsbeteiligung an Robert Schröder

Mehrheitsbeteiligung an Robert Schröder

We are technologically the world's leading manufacturer of high-strength fasteners and a competent partner for the development and production of complex cold-formed parts. We set standards in the areas of innovation, quality, and profitability. In the automotive sector, our core business since the companys foundation, we develop individual solutions for the special requirements of the future in reliable and long-term partnerships with our customers. Our recipe for success: Finding solutions today for the challenges of tomorrow.

Gründung

Der Ingenieur Rudolf Kellermann gründet in Osterode am Harz die „Rudolf Kellermann Fabrik für Gewindeteile“. Mit drei Mitarbeitern und ohne Eigenkapital beginnt er, in einer alten Fassfabrik Schrauben für die Automobilindustrie herzustellen.

Hochfeste Schrauben

Zu dieser Zeit arbeiten schon 76 Mitarbeiter in der jungen Fabrik für Gewindeteile. Nach großen Investitionen in neue Maschinen stellt der Betrieb nun Pleuelschrauben, Radbefestigungs-schrauben, hochfeste Schrauben nach Normvorschriften und Zeichnungen sowie Kleinteile für den Flugzeugbau her.

Labor für Qualitätsprüfung

Während des Zweiten Weltkrieges muss die Fabrik hauptsächlich Schrauben für die Flugzeugindustrie herstellen. Das Werk wird stark vergrößert und die verschiedenen Fertigungsschritte kapazitätsbedingt in unterschiedlichen Gebäuden untergebracht. Zusätzlich wird ein Labor für die Qualitätsprüfung eingerichtet.

Neubeginn

Schon im Sommer 1945 erhält Rudolf Kellermann die Erlaubnis, die Produktion der ursprünglichen Produktpalette wieder aufzunehmen.

Hydraulische Stahlschneidemaschine

Rudolf Kellermann entwickelt zusammen mit seinen Mitarbeitern eine hydraulische Stahlschneidemaschine, um Materialproben entnehmen zu können.

2. Werk in Homberg (Ohm)

In der Fabrik für Gewindeteile in Osterode arbeiten nun über 1.000 Mitarbeiter, die mehr als 6.000 Tonnen Stahl zu Schrauben für die Automobilindustrie verarbeiten. Das Werk stößt an seine Kapazitätsgrenzen und Rudolf Kellermann gründet in Homberg (Ohm) einen zweiten Standort, eine Fabrik für Konstruktionsteile.

Die "Kellermann-Klein" Formel

Rudolf Kellermann untersucht mit Hans-Christof Klein den „Einfluss der Reibung auf Vorspannung und Anzugsmoment von Schraubenverbindungen“ und stellt die „Kellermann-Klein“ Formel auf, die bis heute der weltweite Standard für die Auslegung der Anzugsmomente nach DIN/EN/ISO 16047 ist.

Vollautomatische Herstellung

Die erste Mehrstufenpresse, ein „Boltmaker“ aus den USA, trifft in Homberg (Ohm) ein. Eine Maschine kann nun 70 Schrauben in der Minute herstellen. Dies ist der Beginn der vollautomatischen Produktion von hochfesten Schrauben in Deutschland.

3. Werk in Alsfeld

In Homberg (Ohm) arbeiten inzwischen über 800 Mitarbeiter und das Werk stößt - ähnlich wie 15 Jahre zuvor das Werk in Osterode - an die Grenzen seiner räumlichen Kapazitäten. Im 30 Kilometer entfernten Alsfeld wird der dritte KAMAX Standort gegründet.

Die nächste Generation

Am 13. Dezember, wenige Wochen vor seinem 72. Geburtstag, stirbt Firmengründer Rudolf Kellermann in Altstätten in der Schweiz. Schon vorher hat die nächste Generation der Familie Kellermann Verantwortung im Unternehmen übernommen und stellt nun sicher, dass KAMAX ein unabhängiges Familienunternehmen bleibt.

Lieferung in die USA

KAMAX beliefert erstmals direkt Automobilhersteller in den USA.

Mit dem 4. Werk in Spanien beginnt die Expansion ins Ausland

KAMAX übernimmt die spanische Schraubenfirma TUSA und leitet damit die Internationalisierung ein. Das Werk in Spanien firmiert heute unter KAMAX S.A.U.

Vollautomatisiertes Hochregallager

In Homberg (Ohm) werden im Dezember 1986 eine neue Versandhalle sowie ein vollautomatisiertes Hochregallager eingeweiht. Das neue Regalsystem ist 26 Meter hoch und 55 Meter lang. Computergesteuerte Maschinen können über horizontale und vertikale Führungsschienen innerhalb einer Minute jedes beliebige Fach erreichen.

5. Werk in Tschechien und neues Entwicklungszentrum

In der tschechischen Stadt Turnov baut KAMAX ein komplett neues Werk, das fünfte der Firmengruppe. In Homberg (Ohm) wird ein hochmodernes Entwicklungszentrum eingeweiht. Dies ermöglicht KAMAX, sich durch umfangreiche Forschungs- und Entwicklungsprojekte im Markt zu differenzieren.

Übernahme G.P. DUPONT in den USA (Werke 6,7 und 8)

KAMAX fasst durch die 100%ige Übernahme des Schraubenherstellers G.P. DUPONT in Detroit, Michigan erfolgreich Fuß in Amerika.

Gründung von "FACIL"

Die dritte

Unternehmergeneration von KAMAX gründet zusammen mit dem

französischen Automobilzulieferer

A. RAYMOND im belgischen Genk

den Full Service Provider FACIL („Fasteners and Connections

International“). FACIL bietet alle Verbindungselemente für die

Automobilindustrie aus einer Hand an.

Teile für 1 Million Fahrzeuge

FACIL operiert inzwischen an drei Standorten. Für die Herstellung von mehr als 1 Million Fahrzeugen pro Jahr werden Teile von FACIL verwendet.

Lieferung nach China

KAMAX beliefert erstmals direkt Automobilhersteller in China.

FACIL mit 8 Standorten

Der Erfolg des FACIL-Konzeptes wird in die Nutzfahrzeug-Industrie übernommen. Facil operiert nun bereits an 8 Standorten.

Modernisierung und Erweiterung

Im Mai wird in Homberg (Ohm) die neue Werkstoffoberflächen-Behandlungsanlage in Betrieb genommen. In den USA ist das Werk in Lapeer mittlerweile durch gezielte Investitionen eines der modernsten des Landes und wird zusätzlich um zwei große Produktionshallen erweitert.

Werkzeugbau in der Slowakei als 9. Produktionsstandort

Im November wird das neu gebaute Werk in Bardejov, Slowakei, eröffnet. KAMAX produziert nun mit mehr als 2.500 Mitarbeitern an weltweit neun Standorten.

Globale Kooperation mit der Aoyama Seisakusho-Gruppe in Japan

KAMAX startet eine umfassende und globale Kooperation mit der japanischen Aoyama Seisakusho-Gruppe.

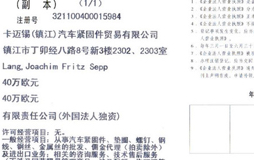

Vertriebsgesellschaften in China und Japan

KAMAX verstärkt sein Engagement in Asien durch Gründung von Vertriebsgesellschaften in China und Japan.

Neues Logistikzentrum in Tschechien

Im Januar wird im tschechischen Turnov Vesecko, in unmittelbarer Nähe zum bereits bestehenden KAMAX Werk, ein neues Logistikzentrum eröffnet, das den gestiegenen Kapazitätsanforderungen begegnet.

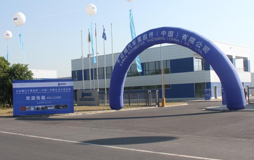

Neuer Produktionsstandort in China

Im September wird in der chinesischen Stadt Changzhou ein neues Produktionswerk offiziell eröffnet, welches über hochmoderne Gebäude- und Produktionstechnik verfügt. Die Eröffnung des Werkes in China stellt einen wichtigen Meilenstein im Rahmen der Gesamt-Unternehmensstrategie dar.

KAMAX jetzt auch in Indien

Im Zuge der globalen Expansion hat KAMAX eine Vertriebsniederlassung im indischen Bangalore eröffnet. Bei der feierlichen Eröffnung am 17. Juli 2017 nahmen neben Vijay Kumar (einer der beiden Geschäftsführer) auch Mario Braun (Vice President Product Management) und J. Carlos Mena Ivars (Managing Director Finance in Museros) teil, die bei den Vertriebsaktivitäten sowie den strukturellen Anforderungen der Gesellschaft unterstützen.

Neuer Standort in Rochester Hills

KAMAX L.P. hat kürzlich die Abteilungen Vertrieb und Geschäftsentwicklung von Troy nach Rochester Hills verlagert. Die Finanzabteilung sowie der Einkauf nutzen ebenfalls einige Büros der Niederlassung. Vor allem jedoch wurde am neuen Standort ein neues Forschungs- und Entwicklungszentrum errichtet. Mit Wirksamkeit zum 01. Januar 2018 wird sich der Unternehmensname außerdem von KAMAX L.P. zu KAMAX Corporation ändern.

Eröffnung des Aus- und Weiterbildungszentrums in Homberg

Am Hauptsitz in Homberg (Ohm) investiert KAMAX weiter in die langfristige Zukunft des Unternehmens. Für drei Mio. Euro entsteht ein innovatives Aus- und Weiterbildungszentrum, welches insbesondere für die deutschen Standorte sowohl eine hochmoderne Ausbildung der Nachwuchskräfte als auch eine an die aktuellen Herausforderungen angepasste Weiterbildung ermöglicht.

Neuer Standort in León (Mexiko)

KAMAX erweitert die Präsenz in Nordamerika um einen weiteren Standort. Im Industriepark Colinas de León in Mexiko entsteht eine weitere Produktionsstätte, von der aus die lokal ansässigen Automobilhersteller unkompliziert und schnell beliefert werden können. Nach knapp einem Jahr Bauzeit werden Mitte 2019 die ersten Schrauben an Kunden ausgeliefert.

Gründung der nexineer digital GmbH

Um die Digitalisierungsoffensive innerhalb des Unternehmens noch intensiver voranzutreiben, gründet KAMAX die eigenständige nexineer digital GmbH. Das neue Team testet und entwickelt Ideen, um das Tagesgeschäft aller Beschäftigten weltweit mit modernen, digitalen Lösungen für Produktions- und Geschäftsprozesse zu optimieren.

Mehrheitsbeteiligung an Robert Schröder

Um das Produktportfolio zu erweitern, erwirbt KAMAX die Mehrheit an der Robert Schröder Gruppe. Das Unternehmen ist mit vier Standorten weltweit ein Hersteller von Präzisionsteilen sowie komplexen Kaltformteilen in und außerhalb der Automobilindustrie. Durch diesen Produktionsschwerpunkt wird das klassische Produktportfolio der KAMAX Gruppe weiter ausgedehnt – z.B. auf den Bereich E-Bikes und Industriegetriebe.