Innovations

Strong connections with new material concepts and complex geometries

Added values for our customers

Together, we challenge each other to create something new everyday based on our broad knowledge and our creativity. For us, innovations must show a clear differentiation and must impress our customers through added-value during use.

KXprotect

KXprotect is the next-generation solution for ultra-high-strength fasteners.

KXprotect is designed to deliver outstanding performance under extreme conditions. Its austenite-stabilized surface layer provides exceptional resistance to hydrogen while maintaining compatibility with common coating systems. With mechanical properties exceeding 12.9 grades, KXprotect ensures long-lasting reliability for critical fastening applications.

Advantages for our customers

- Higher clamp load and safety thanks to superior hydrogen-resistance performance

- Significantly reduced risk of fastener failure in demanding environments

- Seamless integration into existing production processes due to compatibility with standard coatings and specifications

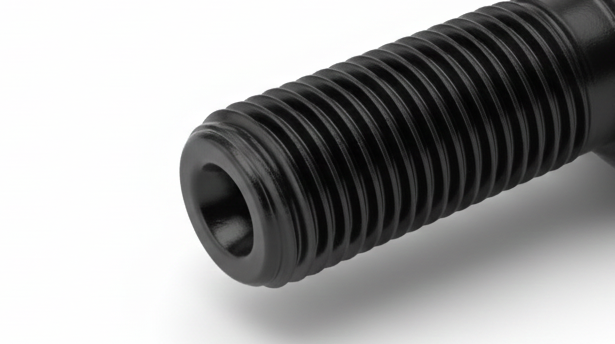

KXguard

Black finish, maximum corrosion protection for wheel bolts

The KXguard is a high-performance coat developed to meet the high performance specifications and demanding corrosion-protection requirements of today’s wheel fasteners. Its durable black finish supports premium visual appearance while maintaining reliable protection also against aggressive rim cleaners and during repeated tightening cycles. KXguard ensures long-lasting performance in real-world vehicle use – proofed by premium OEMs.

Advantages for our customers

- Outstanding corrosion resistance even under harsh chemical exposure.

- Consistent Clamp load in repeated assembly and in the application - also under racetrack driving conditions.

- High-quality black surface appearance that aligns with increasing OEM and end-customer expectations.

KXtwist

The Kamax alternative with higher efficiency for banjo bolts

The flow distribution of our self-developed KXtwist is significantly more consistent and enhancing hydraulic efficiency compared to a conventional design of a banjo bolt. The twisted shape of the bolt offers a less restricted flow – regardless of installation orientation what makes it suitable for any fluid carrying solution.

Advantages for our customers

- More stable flow rate compared to DIN 7643 banjo bolts

- Easy to clean due to external channels

- Cost-optimized design

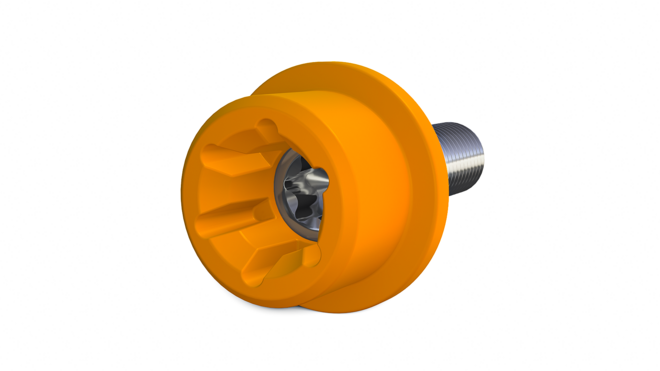

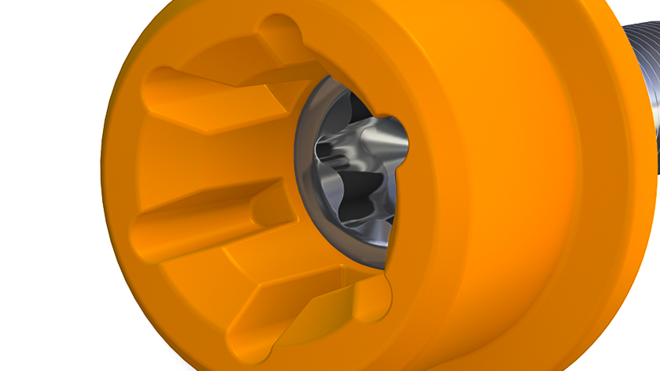

Overmolded Fastener

The Overmolded Fastener by KAMAX for high-voltage environments.

Our solution provides strong electrical insulation directly at the bolt head. Its high clamp load ensures excellent conductivity, making it ideal for busbar connections in e-motors and battery systems. Available in various composite materials and colors, it can be customized to meet specific dielectric and application requirements.

Advantages for our customers

- Enhanced safety and reliability thanks to robust insulation and resistance to disruptive discharge

- Optimal performance in electric drivetrains due to high clamp load and precise, application-specific internal and external drive designs

- Seamless integration into diverse system architectures with customizable materials, colors, and thread sizes from M6 to M20

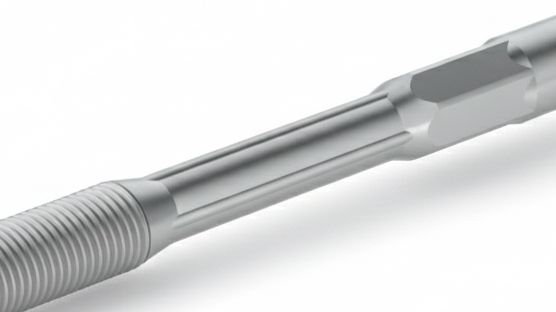

The KAMAX Buckling Groove

Cold forged solution for upgraded Inner Tie Rods

The Inner Tie Rod is a highly durable mechanical linkage connecting the steering gear to the steering knuckle, ensuring precise steering performance. In the event of an accident, the steering gear must be shielded from excessive forces. KAMAX has engineered a specially buckling groove, that provides controlled deformation, and therefore protects the steering system in the event of overload. Manufactured using an advanced cold forging process, it delivers superior strength, consistency, and cost-efficient production.

Advantages for our customers

- More efficient and sustainable production thanks to cold forging, reducing machining effort while improving product quality and cost

- Increased system safety through the integrated buckling groove, which safeguards the steering gear under extreme load conditions

KXgreen

The KAMAX innovation of a sustainable fastener with a reduced carbon footprint

The KXgreen is designed to achieve high mechanical performance without relying on conventional heat-treatment processes without compromises in relaxation. By combining optimized materials with a precisely controlled cold-forming route, KXgreen enables high strength fastener production sustainable. This advanced approach supports more sustainable manufacturing and opens new possibilities for high-performance fastening solutions with low relaxation and high clamp load in applications.

Advantages for our customers

- Identical performance as conventional fasteners according to ISO 898-1

- High and reliable strength levels enabled by material optimization and advanced forming technology

- More sustainable production through reduced energy use and simplified processing steps

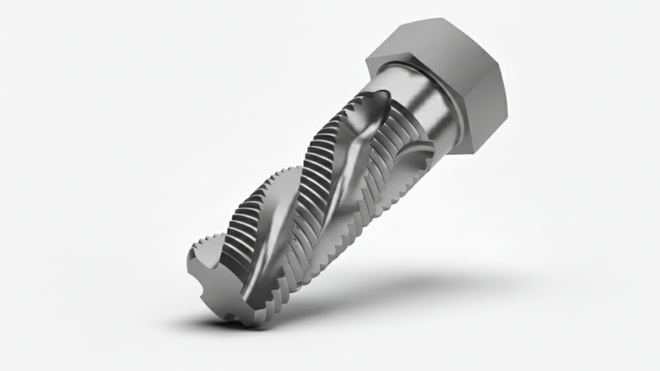

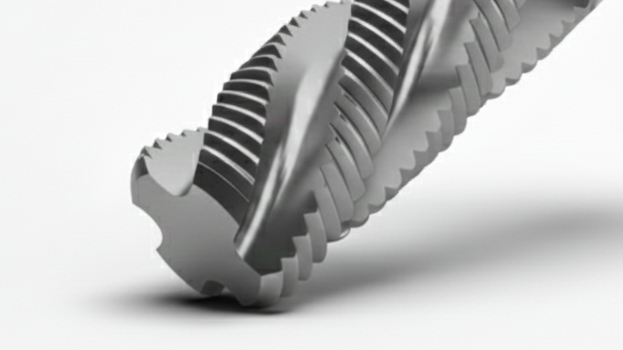

KXtap

The KAMAX alternatives for thread-forming bolts

KXtap stands for self-tapping bolts that even generate their nut thread themselves. The nut thread is produced directly in the stamped, drilled or cast bore through cold-forming during the assembly process. KXtap bolts can be bolted in aluminum and steel.

Advantages for our customers

- Thread cutting is dispensed with

- Bothersome chips are prevented

- Increased load-bearing capacity compared to trilobular self-tapping screws

- Reduced screw-in depths are possible

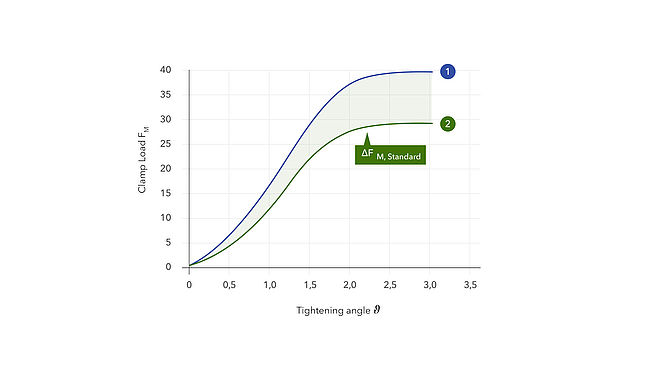

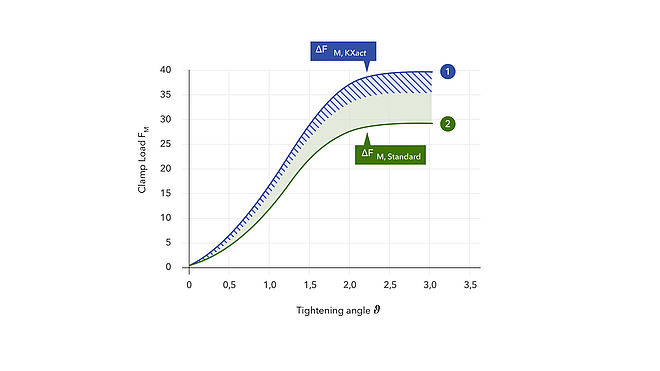

KXact

Restricted tensile strength tolerance to 50 MPa or 80 MPa

For the prescribed assembly method, the strength of the bolt essentially determines the clamping force of the bolted connection that is achieved. The clamping load for high-strength fasteners has a standard range of 150 MPa. Through special measures in process control and material selection, KXact bolts have a restricted range of 50 MPa or 80 MPa. For example, a range of 50 MPa for a class 12.9 bolt corresponds to a tensile strength of 1275 MPa ± 2%.

Advantages for our customers

- High reliability of the connection through a precise preload force window

- Impermissibly high load of the bolting components is prevented

- Through restriction of the lower strength limit, "upsizing" is not necessary

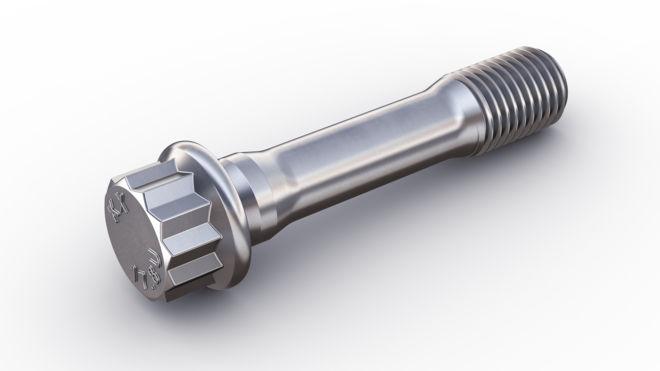

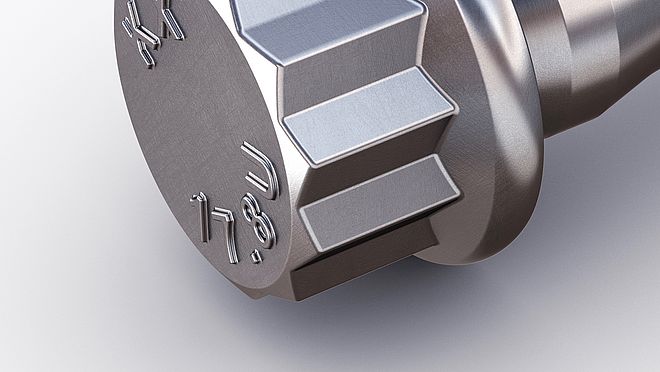

KXtreme

Tensile strength from 1200 to 1700 MPa with simultaneous, outstanding ductility (A5 of class 17.8 > 8%)

Ultrahigh-strength bolts offer connection solutions for highly-stressed and/or weight-sensitive systems. Through the use of KXtreme, the increase in clamping force at constant measurements or the reduction of the measurements at constant clamping force can be used. Through the comprehensive optimization of the product properties, use under corrosion stress is also possible.

Advantages for our customers

- Weight savings and additional install space through reduction of dimensions with the same clamping force

- Clamping force increased by up to 50% for high loads

- By gaining install space, additional function optimization or weight optimization of the surrounding systems is possible

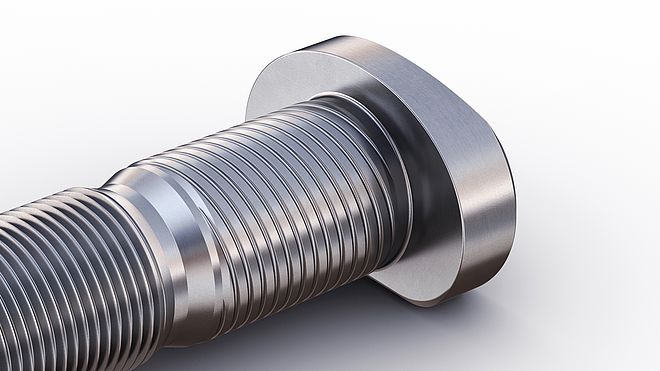

KXhead

Possible double-force application and, at the same time, weight reduction on the bolt head

With the approach of only using material at the right point, significant weight is reduced on the bolt head as well. The difference makes it possible to combine this with additional uses, i.e. the possibility of a standard inside application, outside application or combined application.

Advantages for our customers

- Also backward-compatible for use with existing connection solutions

- Weight savings on the head up to 34 % depending on the size

- Additional functionality through hexagon socket

- No restrictions compared to standard head geometries

- Possible for different sizes from M6 - M24

- Can be combined with all standard coatings

KXfit

Cold-formed fits

Fitting bolts and fitting screws that are produced purely via cold-forming with tolerances to 10 µm; this means that additional processing steps are unnecessary. The utilized geometry achieves a smoothing and further strain hardening of the fitting surface. The special forming of the fitting area generates advantages when pressed in. Moreover, tensions in the connection are reduced.

Advantages for our customers

- The undercut of the profile enables a bore without chamfer

- The fitted bolt can be pressed in and pressed out many times without damaging the bore

- Excellently suited for use in aluminum, steel and cast components